Rice is a staple food for billions of people around the world, and its quality and taste are of utmost importance to those who consume it. One crucial step in the rice production process that significantly impacts its final quality is Rice Rubber Polisher. In this article, we will delve into the world of rice rubber polishers, exploring their importance and how they contribute to enhancing the overall quality and flavor of rice.

Understanding the Rice Rubber Polishing Process

Rice rubber polishing is a critical step in rice milling, particularly for producing white rice. It's the process of removing the outer layer of the rice grain, known as the bran layer or husk, to reveal the inner, starchy endosperm. This polishing not only gives rice its characteristic white appearance but also contributes to its texture and flavor.

The Role of Rice Rubber Polishers

Rice rubber polishers play a pivotal role in ensuring that the rice grains meet the desired quality standards. Here are some key aspects of their function:

Bran Removal: The primary purpose of rice rubber polishers is to remove the bran layer from the rice grains. This not only gives rice its polished appearance but also removes impurities, ensuring that the final product is clean and safe for consumption.

Texture Enhancement: Rice rubber polishing affects the texture of the rice. It smoothens the surface of the grains, making them less likely to stick together during cooking. This results in fluffy and separate rice grains when prepared.

Flavor Improvement: The polishing process can enhance the flavor of rice. By removing the outer layer, the natural flavors of the rice become more pronounced, resulting in a more aromatic and tasty final product.

Longevity: Polished rice has a longer shelf life compared to unpolished or brown rice. This is because the removal of the bran layer reduces the presence of oils that can turn rancid over time.

Types of Rice Rubber Polishers

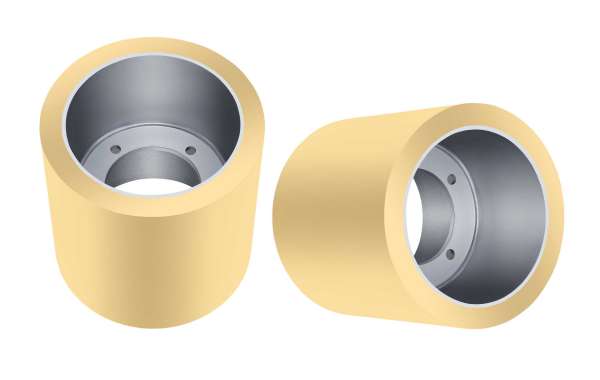

There are various types of rice rubber polishers available, ranging from traditional hand-operated machines to modern, automated equipment used in large-scale rice mills. The choice of rice rubber polisher depends on the scale of production and the specific requirements of rice producers.

Conclusion

In the world of rice production, the rice rubber polisher plays a vital role in shaping the quality, texture, and flavor of the final product. Whether you prefer fluffy white rice or have a penchant for aromatic rice varieties, you can thank the rice rubber polisher for its contribution to the world of rice cuisine. The art of rice rubber polishing continues to evolve, ensuring that rice remains a staple that delights palates worldwide.